Product Overview of Batch Off Machines by Santecgroup

Batch-off machines are a crucial component of the rubber processing industry, designed to handle and cool rubber sheets after they exit mixing mills or kneaders. These machines not only cool the rubber but also allow for easy handling, stacking, and dusting, ensuring high productivity and consistent quality in rubber manufacturing. By maintaining controlled cooling and efficient stacking, Batch Off Machines help industries streamline their operations and reduce manual labor.

Working and Functionality

The Batch Off Machine works by receiving hot rubber sheets, cooling them through an air or water system, and then automatically stacking them in a controlled manner. The machine typically includes a take-off unit, conveyor system, dipping tanks (for anti-tack solution), drying fans, and a stacking unit. This ensures rubber sheets are free from stickiness, properly dried, and ready for the next stage of production.

Applications in Industry

Batch machines are widely used in the rubber industry, tire manufacturing units, conveyor belt industries, and the automotive component production sector. Their ability to provide uniform cooling and prevent sheet sticking makes them indispensable in modern rubber processing plants. They also play a crucial role in enhancing productivity and ensuring the consistency of rubber compounds.

Advantages of Using Batch Off Machines

These machines reduce manual labor, increase efficiency, and provide consistent product quality. With features like automatic stacking, adjustable conveyors, and efficient cooling systems, they minimize errors and save significant production time. Furthermore, their robust design ensures durability and long operational life, making them a cost-effective investment for industries.

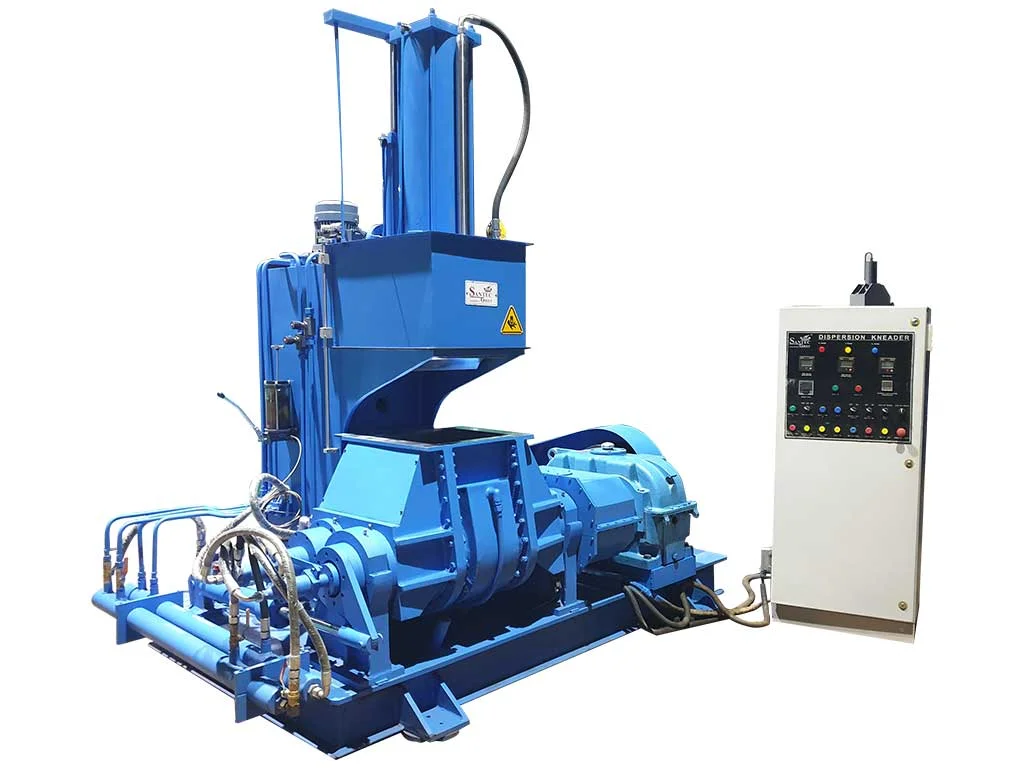

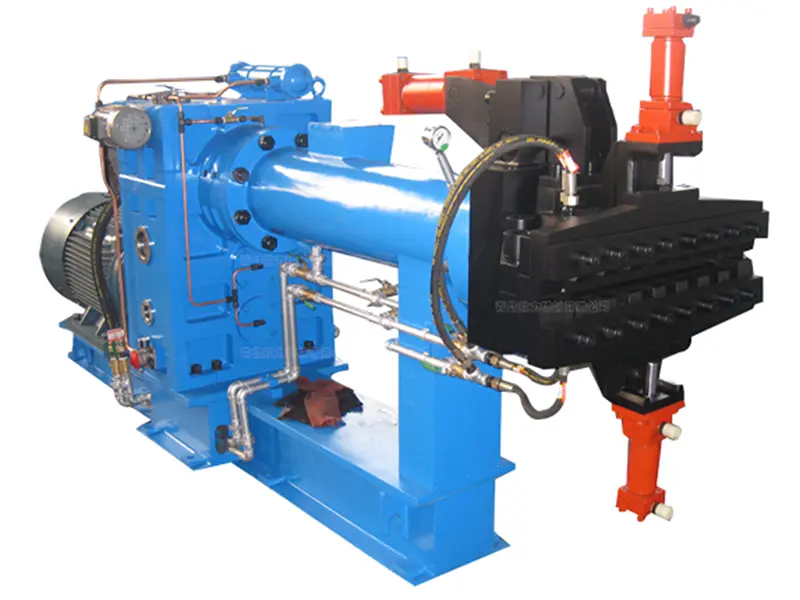

About Santecgroup – Trusted Name in Rubber Machinery

Santec Group is one of the leading manufacturers and suppliers of high-quality rubber and plastic machinery, renowned for its advanced technology and durable machines. With decades of expertise, the company has built a reputation for delivering innovative and reliable solutions tailored to customer requirements. Headquartered in Calcutta, Santec Group specializes in Batch-off Machines that are engineered with precision and efficiency to meet the demanding needs of the rubber industry worldwide.

Batch Off Machines

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Calcutta

₹1,250,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Heavy-duty structure with robust design.

- Automatic sheet stacking system.

- Advanced cooling with air and water circulation.

- Anti-tack dipping and drying system.

- Easy operation with minimal manual handling.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Sheet Width Capacity | 400 mm to 1200 mm |

| Cooling System | Air / Water cooled |

| Stacking System | Manual / Automatic |

| Conveyor Speed | Adjustable (Variable Frequency Drive) |

| Dipping Tank | With Anti-Tack Solution Facility |

| Drying System | High-speed fans / Blowers |

| Power Requirement | 20 HP – 60 HP (depending on model) |

| Sheet Thickness Handling | 3 mm – 15 mm |

| Production Capacity | Customizable as per client needs |

| Frame | Heavy-duty fabricated steel structure |

Product Benefits

-

Enhances productivity with efficient cooling and stacking.

-

Reduces manual labor requirements.

-

Ensures uniform sheet quality.

-

Prevents sticking of rubber sheets.

-

Long-lasting and durable design.

-

Saves production time with automation.

-

Easy maintenance and operation.

-

Improves safety in rubber handling.

-

Energy-efficient cooling systems.

-

Suitable for a wide range of rubber applications.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

It is used for cooling, drying, and stacking rubber sheets after mixing.

Yes, it is customizable for different widths and thicknesses.

Yes, both manual and automatic stacking models are available.

Rubber sheets are dipped in an anti-tack solution to prevent sticking.

Tire, automotive, conveyor belt, and general rubber industries.

The company is headquartered in Calcutta, India.

Rubber, plastic, and hydraulic machinery.

Yes, the company exports globally to many countries.

The company has decades of experience in the industry.

Yes, they provide strong after-sales support and maintenance services.

Starting price is around ₹12,50,000/-.

Typically 10–15 years with proper maintenance.

Yes, it can be tailored to specific requirements.

It varies between 20 HP to 60 HP, depending on the model.

Space depends on the capacity; usually 15–20 ft length is needed.