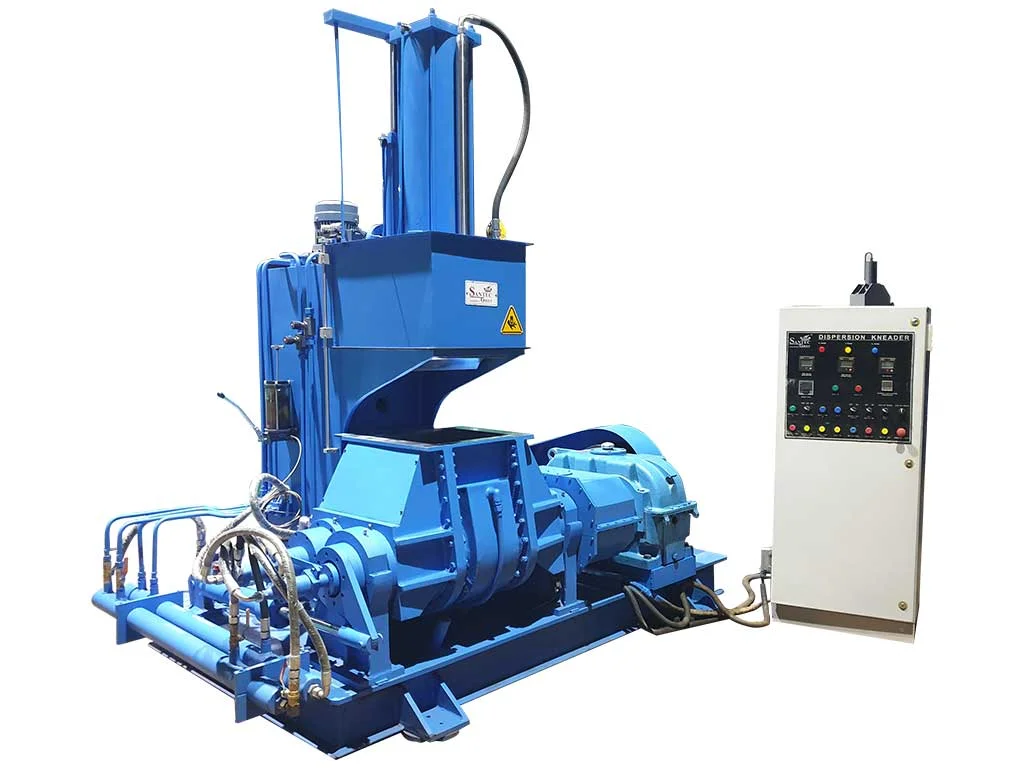

Product Overview: Bladder Curing Presses

Bladder Curing Presses are highly efficient machines designed for the vulcanization and curing of tire bladders, an essential component in tire manufacturing. These presses are engineered to provide uniform heat, pressure, and precision, ensuring consistent product quality in every production cycle. They are widely used by tire manufacturers for curing inner tire bladders, ensuring durability, flexibility, and superior performance.

Design and Construction

The presses are designed with heavy-duty steel frames, hydraulic systems, and advanced heating controls to provide superior stability and reliability. Their robust design allows for continuous operation under high-pressure conditions, making them ideal for large-scale production lines. The ergonomic construction also ensures ease of maintenance and operator safety.

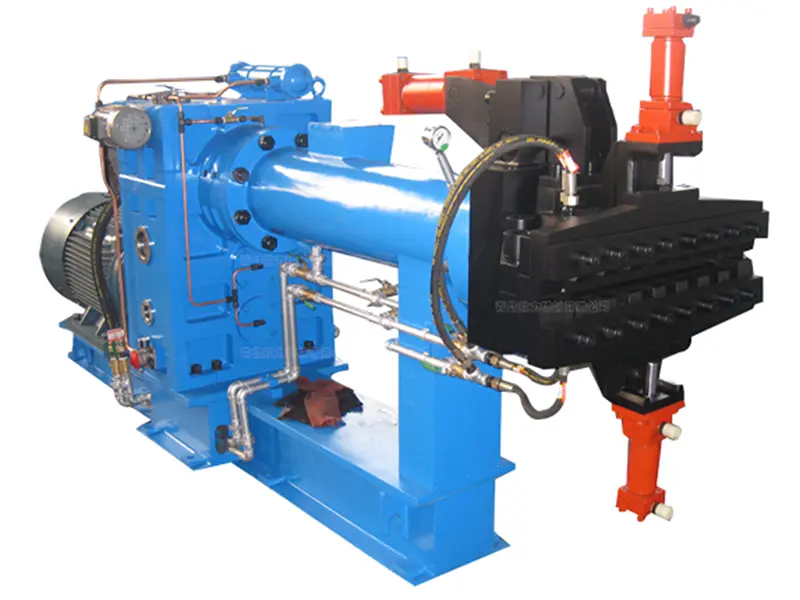

Working Mechanism

Bladder Curing Presses work by applying controlled heat and pressure to rubber compounds, transforming them into a finished bladder with high strength and resilience. The hydraulic system ensures a consistent clamping force, while the precision temperature control allows for uniform curing without material degradation.

Applications

* Tire bladder production for passenger vehicles, trucks, and heavy-duty vehicles.

* Specialized rubber curing applications in the automotive and industrial sectors.

* Used in large tire manufacturing plants to achieve efficiency and consistency.

About Santecgroup

Santecgroup, based in Calcutta, is one of the leading manufacturers and suppliers of Bladder Curing Presses in India. With decades of expertise in hydraulic presses and rubber processing machinery, the company has built a reputation for delivering innovative, durable, and cost-efficient solutions to industries worldwide. Their Bladder Curing Presses in Calcutta are trusted by major tire manufacturers for precision engineering, high performance, and long service life.

Bladder Curing Presses

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Calcutta

₹1,200,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Heavy-duty welded steel frame for durability.

- Advanced hydraulic system for consistent pressure.

- Precision temperature controls for uniform curing.

- User-friendly interface with safety features.

- High productivity with minimal downtime.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Frame | Welded steel construction |

| Capacity | 50 – 200 tons (customizable) |

| Heating System | Electrical/steam heating plates |

| Control System | PLC-based with HMI interface |

| Pressure Range | 50 – 150 kg/cm² |

| Curing Cycle Time | Adjustable |

| Safety Features | Emergency stop, overload protection |

| Power Supply | 220V/380V, 50 Hz |

| Automation | Semi-automatic/fully automatic options |

Product Benefits

-

Ensures uniform curing of tire bladders.

-

Reduces operational costs with efficient energy use.

-

Increases production capacity for large-scale operations.

-

Provides long-lasting performance with minimal maintenance.

-

Enhances safety with reliable hydraulic and control systems.

-

Minimizes human errors through automated functions.

-

Compatible with a variety of rubber compounds.

-

Reduces cycle time, improving overall output.

-

Environment-friendly with efficient energy utilization.

-

Increases return on investment through durability and efficiency.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

It is used to cure tire bladders by applying heat and pressure.

Yes, it can be customized for various bladder sizes.

Electrical and steam heating systems are available.

Yes, it is designed for heavy-duty industrial use.

It is controlled through a PLC-based system with adjustable settings.

Santecgroup is headquartered in Calcutta, India.

The company has decades of experience in hydraulic and rubber machinery manufacturing.

Yes, they provide tailor-made solutions as per client requirements.

Yes, the company offers full after-sales service and spare parts support.

Yes, they supply machinery to industries across the globe.

Starting at ₹12,00,000/- (approx.).

With proper maintenance, it can last 15–20 years.

Consumption depends on capacity, typically moderate for industrial use.

Yes, training is provided at installation.

Yes, advanced automation reduces cycle time significantly.