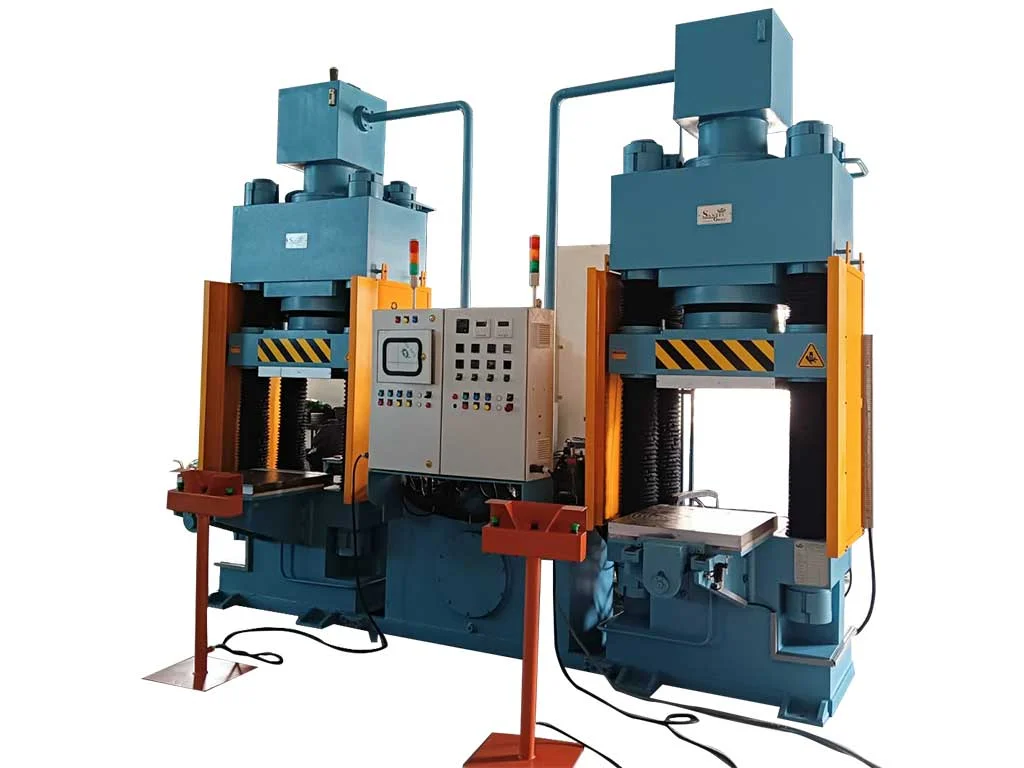

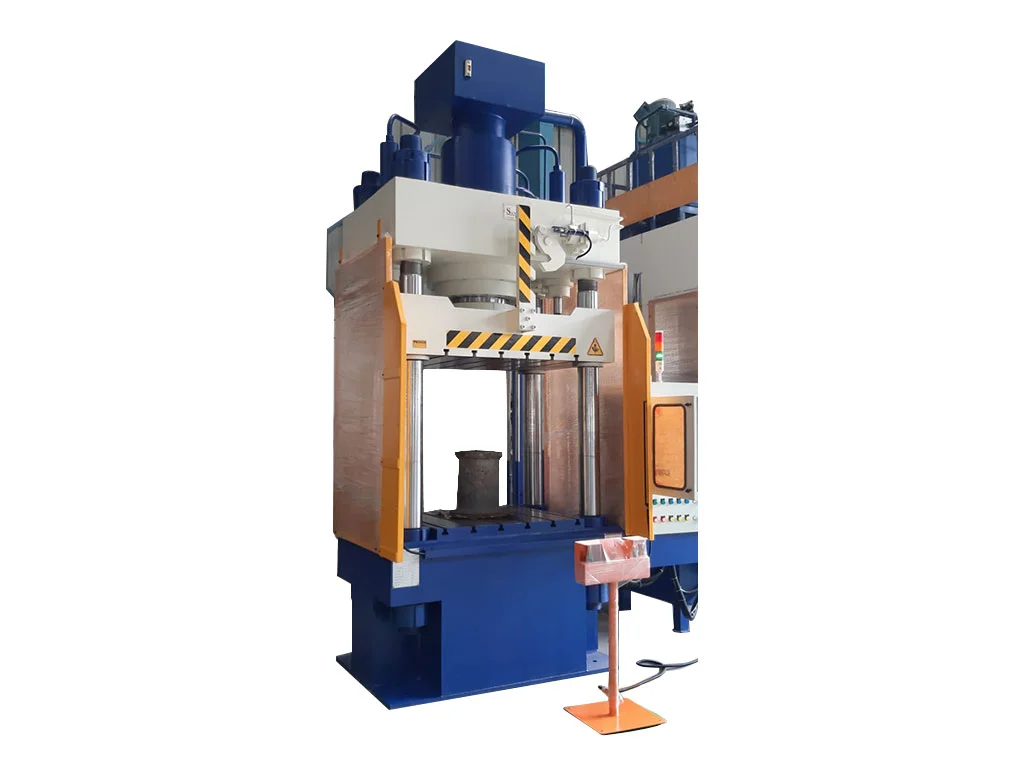

Product Overview: Bridge Bearing Moulding & Testing Machines

Bridge bearing moulding and testing machines are essential equipment in the infrastructure and construction industry. They are designed to evaluate and test the strength, performance, and durability of bridge bearings under both vertical and horizontal loads. These machines play a crucial role in ensuring that bridge structures remain safe, stable, and long-lasting.

Importance of Bridge Bearing Testing

Bridge bearings act as a critical interface between a bridge deck and its supporting piers. They are exposed to heavy loads, vibrations, and changing environmental conditions. Without proper testing, these bearings could fail, leading to structural risks. The moulding and testing process ensures that the materials and bearings meet industry standards and can withstand real-world stresses.

Vertical and Horizontal Load Testing

Bridge bearing testing machines are capable of applying both vertical and horizontal loads, simulating the exact forces that bearings face in practical use. Vertical load testing checks compressive strength and load-carrying capacity, while horizontal load testing evaluates movement, flexibility, and resilience against lateral forces. Together, they guarantee optimal performance.

Applications

* Testing of elastomeric bridge bearings

* Load testing for sliding bearings

* Quality assurance in bridge construction projects

* Compliance with national and international standards

* Research and development in structural engineering

Why Choose Bridge Bearing Moulding & Testing Machines?

Investing in advanced moulding and testing equipment ensures that every bridge component undergoes rigorous quality checks before installation. This minimizes risks of structural failure and improves the lifespan of critical infrastructure.

About Santec Group Corporation

Santec Group Corporation is one of the leading manufacturers and suppliers of bridge bearing moulding and testing machines in Calcutta. With years of engineering expertise, Santec provides highly durable and efficient machines that meet global quality standards. Known for reliability, innovation, and cost-effectiveness, the company serves construction firms, government projects, and research institutes. By offering advanced vertical and horizontal load testing machines at competitive prices, Santec Group has become a trusted partner in the development of robust and safe infrastructure across India.

Bridge Bearing Moulding Testing vertical horizontal Load

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Calcutta

₹450,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Advanced vertical and horizontal load testing capability.

- High-precision hydraulic systems.

- Robust construction for long-term durability.

- User-friendly digital control panel.

- Compliance with IS and international testing standards.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Load Capacity (Vertical) | Up to 5000 kN |

| Load Capacity (Horizontal) | Up to 1000 kN |

| Control System | Digital display with automated data logging |

| Hydraulic System | High-pressure, energy-efficient pumps |

| Frame Structure | Heavy-duty steel frame for stability |

| Accuracy | ±1% of applied load |

| Power Requirement | 3-phase, 415 V, 50 Hz |

| Testing Standards | IS, IRC, ASTM compliant |

| Safety Features | Emergency stop, overload protection |

| Cooling System | Oil circulation with heat exchanger |

Product Benefits

-

Ensures structural safety of bridges.

-

Increases lifespan of bridge bearings.

-

Minimizes risks of mechanical failure.

-

Enhances efficiency in testing procedures.

-

Reduces maintenance costs in infrastructure.

-

Provides accurate and reliable test results.

-

Supports compliance with government standards.

-

Suitable for multiple types of bearings.

-

Helps in R&D and product development.

-

Cost-effective investment for construction companies.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

It is a machine used to test bridge bearings under vertical and horizontal loads to ensure safety and performance.

Yes, it is suitable for testing different types of bridge bearings.

Up to 5000 kN vertically and 1000 kN horizontally.

Yes, it comes with a user-friendly digital control system.

Yes, it meets IS, IRC, and ASTM standards.

The company is based in Calcutta, India.

Primarily construction, infrastructure, and research institutions.

Yes, complete installation and training are provided.

Advanced technology, affordable pricing, and reliable service support.

Yes, Santec supplies globally along with pan-India distribution.

It ensures bridge safety and prevents structural failures.

During manufacturing, installation, and periodically during maintenance.

Starting from ₹4,50,000/- depending on specifications.

With proper maintenance, it can last over 15 years.

Yes, customization is available based on client requirements.