Product Overview of Rubber Extruders

Rubber extruders are essential machinery used in the rubber processing industry for shaping raw rubber compounds into continuous profiles of specific cross-sections. These machines play a crucial role in manufacturing a wide range of products, including tubes, pipes, seals, cables, weatherstrips, and other customized profiles. By forcing the rubber through a die, rubber extruders ensure uniformity, precision, and quality in the final output, making them indispensable for industries ranging from automotive to construction.

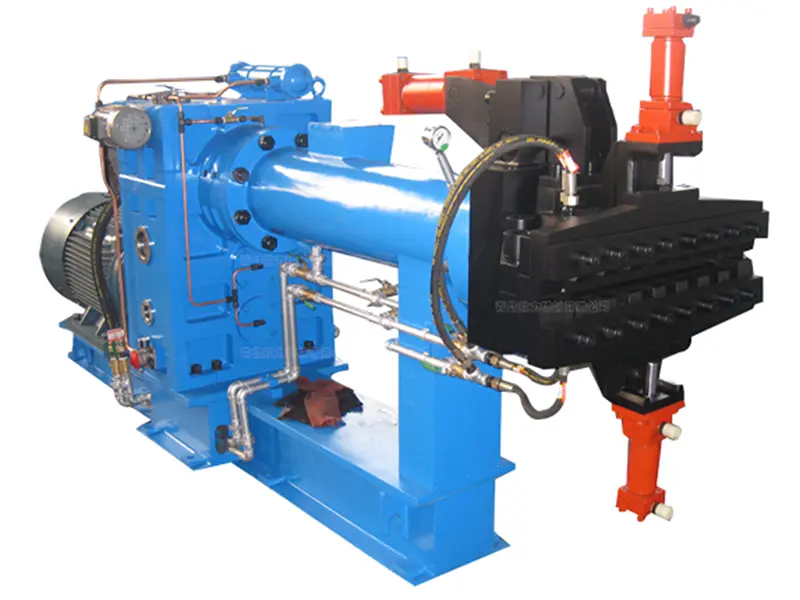

Working Principle of Rubber Extruders

A rubber extruder works by feeding raw or pre-heated rubber material into a rotating screw housed within a heated barrel. The screw conveys the material forward, applying both pressure and heat to soften and plasticize it. The molten rubber is then forced through a specially designed die to create the desired shape. This process ensures consistent production, improved dimensional accuracy, and minimal material wastage.

Applications of Rubber Extruders

Rubber extruders find versatile applications across industries. They are widely used in:

* Automotive industry for seals, gaskets, and hoses.

* The electrical industry for insulated cables and wires.

* Construction industry for weather-stripping, window profiles, and sealing materials.

* Consumer products such as tubes, pipes, and footwear components.

Their adaptability makes them an essential machine for both small-scale and large-scale manufacturing.

Types of Rubber Extruders

Depending on production requirements, rubber extruders come in different variants, including:

* Cold Feed Extruders: Used for better efficiency and continuous processing.

* Hot Feed Extruders: Suitable for pre-heated rubber materials.

* Co-Extruders: Designed for multi-layer or composite profiles.

* Pin-Barrel Extruders: Known for higher output and better mixing properties.

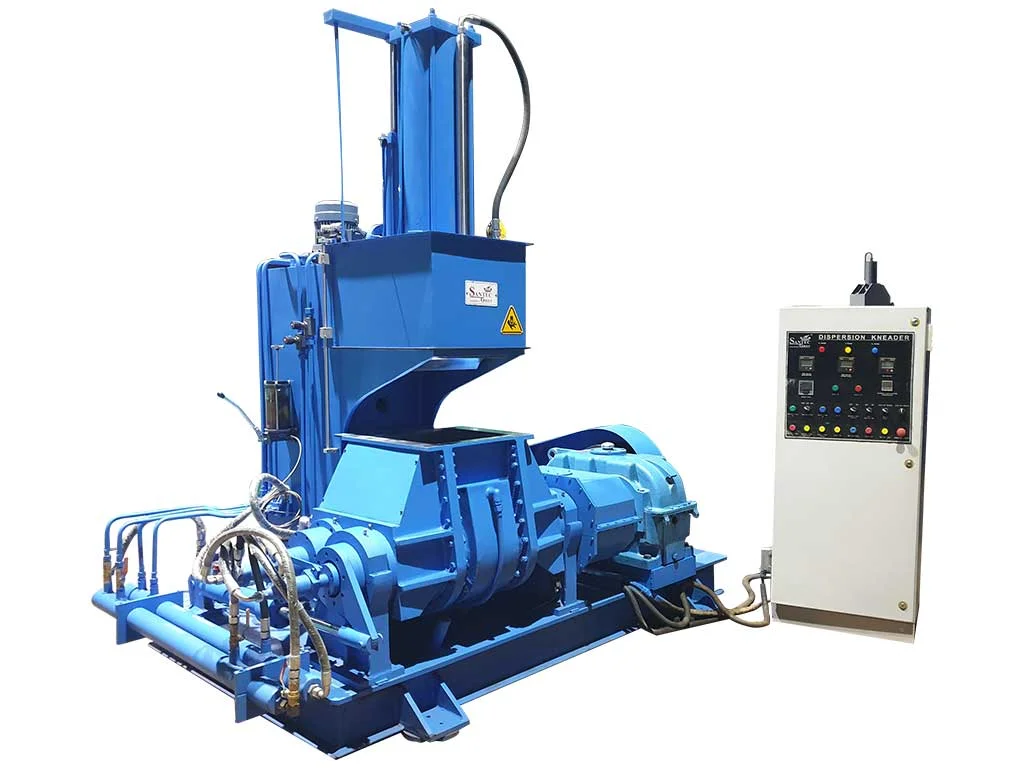

Why Choose Santecgroup Rubber Extruders?

Santecgroup is one of the leading manufacturers and suppliers of rubber extruders, delivering advanced machines with unmatched reliability and performance. The company ensures robust designs, precision engineering, and energy efficiency, catering to a diverse range of industrial needs. Based in Calcutta, Santecgroup has built a strong reputation for delivering world-class rubber machinery that meets international quality standards. Their rubber extruders are designed to provide consistent output, reduce downtime, and offer high durability, making them the preferred choice among industries across India and worldwide.

Rubber Extruders

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Calcutta

₹750,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- High-performance screw and barrel design.

- Robust construction for long service life.

- Energy-efficient heating and cooling system.

- Easy-to-operate control panel.

- Customizable die design for versatile applications.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Screw Diameter | 55 mm to 200 mm |

| L/D Ratio (Length to Diameter) | 12:1 to 20:1 |

| Output Capacity | 50 kg/hr to 1200 kg/hr (varies by model) |

| Drive Motor Power | 15 HP to 250 HP |

| Heating System | Electrical/Steam |

| Cooling System | Water/Air cooled |

| Material Processed | Natural & Synthetic Rubber Compounds |

| Control System | PLC/Manual with safety features |

Product Benefits

-

Consistent and high-quality output.

-

Reduced material wastage.

-

Increased production efficiency.

-

Suitable for a wide range of rubber compounds.

-

Enhanced product uniformity and precision.

-

Lower maintenance costs.

-

Extended equipment life.

-

User-friendly operation.

-

Cost-effective production.

-

High adaptability for various industrial uses.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

It shapes rubber compounds into continuous profiles through a die.

Natural rubber, synthetic rubber, and elastomer blends.

Automotive, electrical, construction, and consumer goods.

Yes, they can be tailored to meet specific production needs.

With proper maintenance, it can last over 10–15 years.

The company is based in Calcutta, India.

Rubber machinery, hydraulic presses, and plastic processing machines.

Yes, they provide installation, training, and service support.

Yes, they export machines globally.

The company has decades of experience in manufacturing.

Starts from ₹7,50,000/- depending on size and features.

Regular lubrication, timely inspection, and cleaning.

Hot feed requires pre-heated rubber, cold feed processes directly.

Yes, with proper screw design and die.

50 kg/hr to 1200 kg/hr depending on model.