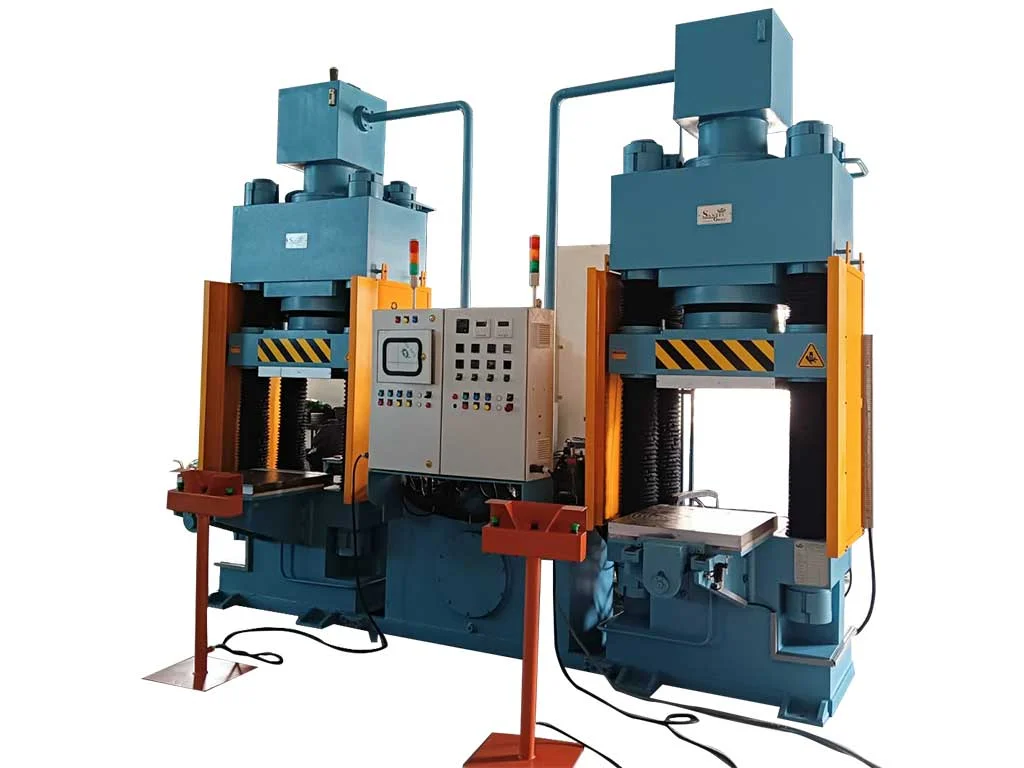

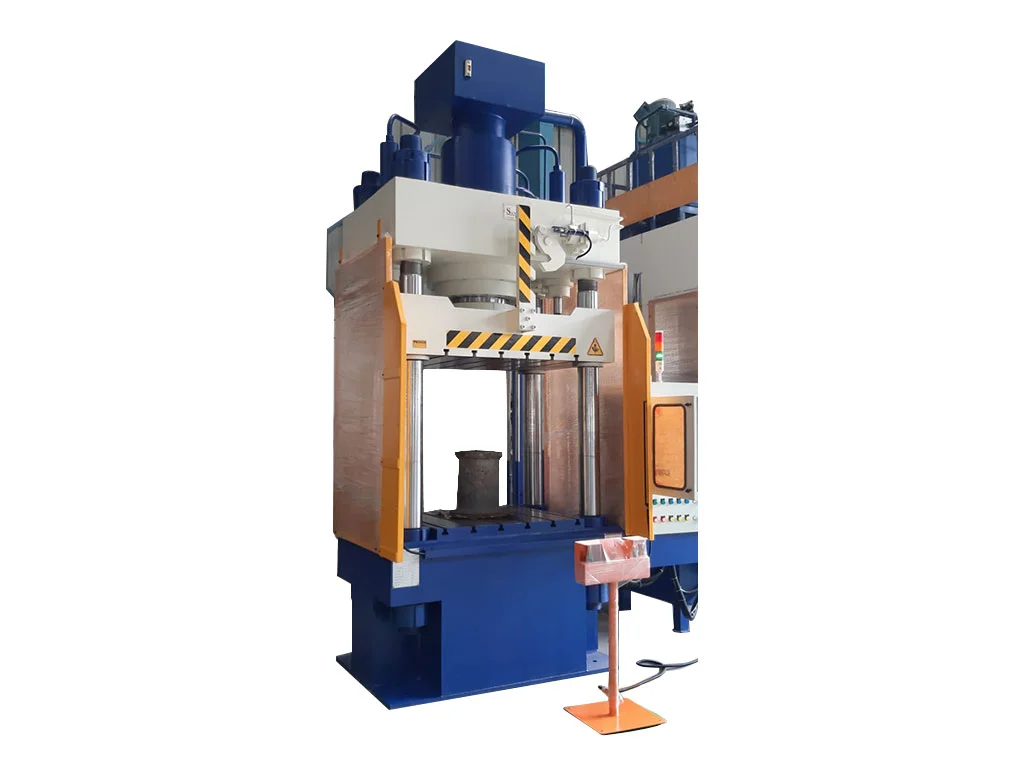

Composite Moulding Press Machine – Product Overview

Introduction

Composite materials are widely used across various industries, including automotive, aerospace, defense, and electrical, due to their high strength-to-weight ratio, durability, and versatility. To shape these advanced materials with precision, a Composite Moulding Press Machine is essential. These machines ensure consistent performance, high productivity, and defect-free moulding of fiber-reinforced composites, thermoplastics, and thermosets.

What is a Composite Moulding Press Machine?

A Composite Moulding Press Machine is a hydraulic press designed for moulding composite materials under controlled temperature and pressure. It uses advanced hydraulic technology to compress and cure raw composite sheets or fibers into complex shapes, ensuring accuracy, uniformity, and strength in the final product.

Why Choose a Composite Moulding Press?

The demand for lightweight and high-performance products is driving industries to adopt composite moulding solutions. These presses enable manufacturers to produce robust, reliable, and corrosion-resistant products that meet current industrial standards. From automobile body parts to aerospace components, composite moulding presses are an essential investment for quality-driven industries.

Applications of Composite Moulding Press Machines

* Automotive parts (interior & exterior panels, bumpers)

* Aerospace components

* Defense equipment

* Electrical housings and insulators

* Sporting goods and helmets

* Industrial tools and machinery housings

About Santec Group Corporation

Santec Group Corporation, based in Delhi, is one of the leading manufacturers and suppliers of Composite Moulding Press Machines in India. With years of expertise in hydraulic and mechanical press technologies, Santec has built a strong reputation for delivering high-performance, durable, and cost-effective machinery. The company caters to both domestic and global markets, offering customized solutions tailored to industry-specific needs. When buying from Santec, customers can expect not only world-class machines but also exceptional after-sales service and competitive pricing.

Composite Moulding Press Machine

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Delhi

₹650,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Heavy-duty hydraulic press with precision controls

- Programmable temperature and pressure settings

- High structural rigidity for long-term performance

- User-friendly PLC-based control system

- Energy-efficient design with low maintenance requirements

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Press Type | Hydraulic Composite Moulding Press |

| Capacity | 50 Tons – 3000 Tons (customizable) |

| Platen Size | 500 x 500 mm to 3000 x 2500 mm |

| Heating System | Electric / Steam / Oil Heated |

| Control Panel | PLC/HMI-based fully automated controls |

| Mould Closing Speed | Adjustable (10–50 mm/sec) |

| Temperature Range | Up to 350°C |

| Ejector System | Available on request |

| Power Source | 3 Phase, 415V, 50 Hz AC |

| Safety Features | Emergency stop, safety guards, interlocks |

Product Benefits

-

Ensures high-quality composite moulding

-

Reduces production time with faster cycle completion

-

Produces uniform and defect-free products

-

Suitable for complex and large moulds

-

Enhances product durability and finish

-

Supports a wide range of composite materials

-

Increases production efficiency and consistency

-

Low operational cost with high output

-

Reliable performance with minimal downtime

-

Long service life, ensuring value for money

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

It moulds and shapes composite materials under heat and pressure for industrial applications.

Yes, Santec’s machines are designed for both material types.

Absolutely, machines can be tailored to customer specifications.

Yes, it features advanced temperature and pressure control systems.

Automotive, aerospace, defense, electrical, and sports equipment industries.

Santec Group Corporation is headquartered in Delhi, India.

The company has decades of experience in manufacturing hydraulic presses.

Yes, installation, commissioning, and operator training are provided.

Yes, Santec provides genuine spare parts and after-sales support.

Yes, the company supplies to both domestic and international markets.

The starting price is approximately ₹6,50,000.

Capacity depends on mould size, material type, and production requirements.

Power consumption varies with capacity but is optimized for efficiency.

Generally, 6–8 weeks depending on customization.

Financing options may be available through third-party providers.