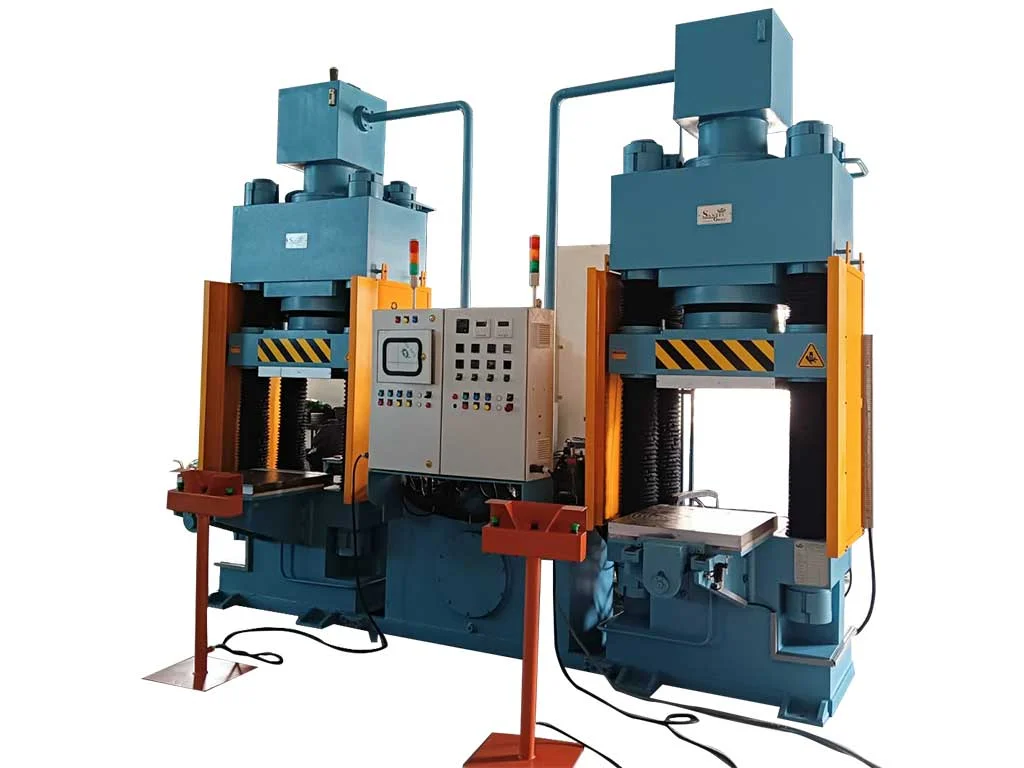

Compression Moulding Presses for Marine Fenders – Product Overview

Compression moulding presses are essential equipment in the marine industry for producing high-quality marine fenders. These machines ensure durability, precision, and performance in demanding marine environments. Santec Group Corporation, a renowned name in the manufacturing sector, offers advanced Compression Moulding Presses for Marine Fenders in Delhi at competitive prices.

What are Compression Moulding Presses?

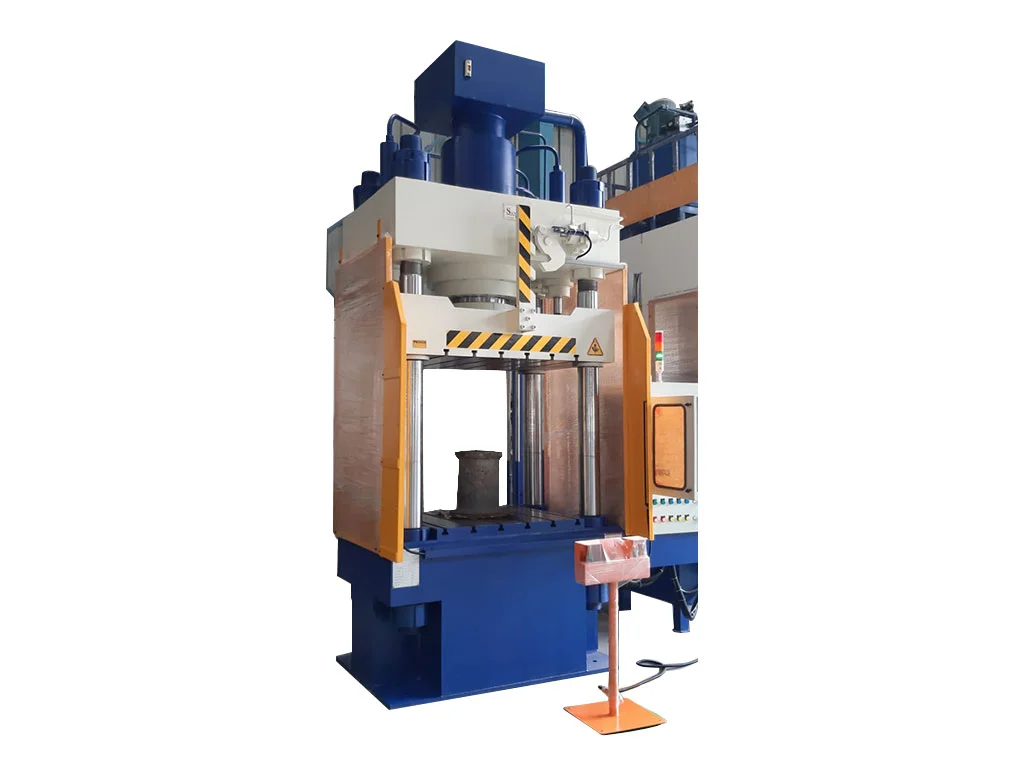

Compression moulding presses are heavy-duty machines designed to mould rubber and composite materials under high pressure and temperature. In the case of marine fenders, these presses shape and strengthen rubber components to withstand extreme impact, ensuring vessel safety during docking and berthing.

Why Marine Fenders Need Compression Moulding?

Marine fenders absorb energy and prevent damage to ships and port structures. The manufacturing process demands machines that can mould rubber with consistency and strength. Santec’s compression moulding presses guarantee reliable performance and extend the lifespan of marine fenders, making them indispensable for ports, shipyards, and maritime operations.

Advantages of Using Santec’s Compression Moulding Presses

Santec presses are engineered with cutting-edge technology, offering precise control over pressure and temperature. This ensures uniform product quality and reduces rejection rates. The machines are designed for energy efficiency, operator safety, and low maintenance costs, making them a cost-effective investment for manufacturers.

Applications in the Marine Industry

* Manufacturing cylindrical fenders

* Shaping cone fenders

* Production of cell-type fenders

* Customised fender moulding solutions

About Santec Group Corporation

Santec Group Corporation, based in Delhi, is a leading manufacturer and supplier of industrial presses, including hydraulic presses, rubber moulding presses, and compression moulding presses. With decades of expertise and a reputation for quality, Santec has established itself as a trusted supplier to industries worldwide. Their Compression Moulding Presses for Marine Fenders are designed with durability, safety, and innovation in mind, making them a preferred choice in the maritime sector.

Compression Moulding Presses for Marine Fenders

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Delhi

₹1,200,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- High-tonnage capacity for heavy-duty moulding.

- Advanced hydraulic system with precise pressure control.

- Programmable logic controller (PLC) for automated operation.

- Energy-efficient and low-maintenance design.

- Safety interlocks and user-friendly interface.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Type | Hydraulic Compression Moulding Press |

| Capacity | 100 to 3000 tons (customizable) |

| Platen Size | 400 mm × 400 mm up to 3000 mm × 3000 mm |

| Heating System | Electric / Steam / Thermic Fluid |

| Temperature Range | Up to 300°C |

| Control System | PLC / Manual / Semi-automatic |

| Power Supply | 3 Phase, 415 V, 50 Hz |

| Construction | Heavy-duty welded frame structure |

| Cycle Time | Adjustable depending on material and design |

| Applications | Marine fenders, rubber components, industrial mouldings |

Product Benefits

-

Ensures long-lasting marine fenders.

-

Reduces material wastage.

-

Enhances production efficiency.

-

Provides consistent product quality.

-

Minimizes downtime with durable construction.

-

Easy to operate with automated features.

-

Supports high-volume production.

-

Designed for safety and operator comfort.

-

Reduces maintenance costs.

-

Suitable for different types of marine fenders.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

The presses are available from 100 to 3000 tons, depending on customer requirements.

Yes, they can produce cylindrical, cone, and cell-type fenders.

Electric, steam, and thermic fluid heating systems are provided.

Absolutely, they are designed for continuous, high-volume operations.

Safety interlocks, overload protection, and emergency stop systems are standard.

The company is based in Delhi, India.

Santec has decades of experience in manufacturing hydraulic and moulding presses.

Yes, they offer installation, training, and maintenance services.

Yes, Santec serves customers worldwide.

Yes, machines are tailored to meet specific industrial needs.

It is a machine that uses heat and pressure to mould rubber or composites into desired shapes.

They protect ships and port structures from damage during docking.

With proper moulding and materials, they can last several years under harsh conditions.

Automotive, aerospace, marine, and rubber product industries.

Capacity, platen size, heating system, and automation level influence the cost.