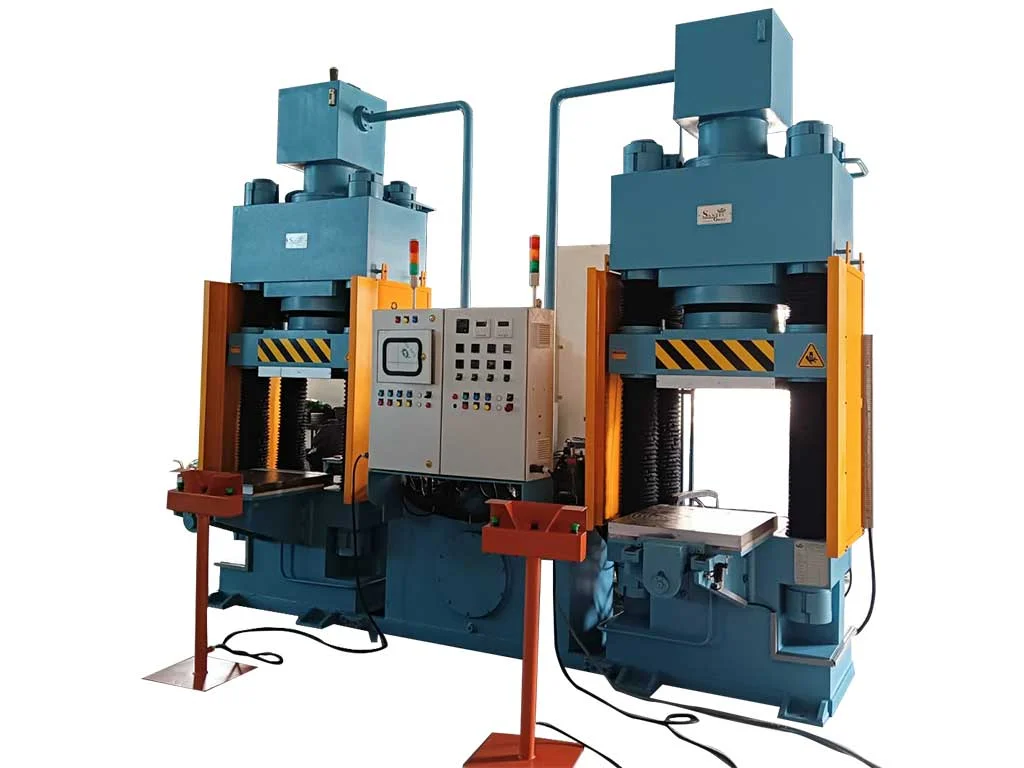

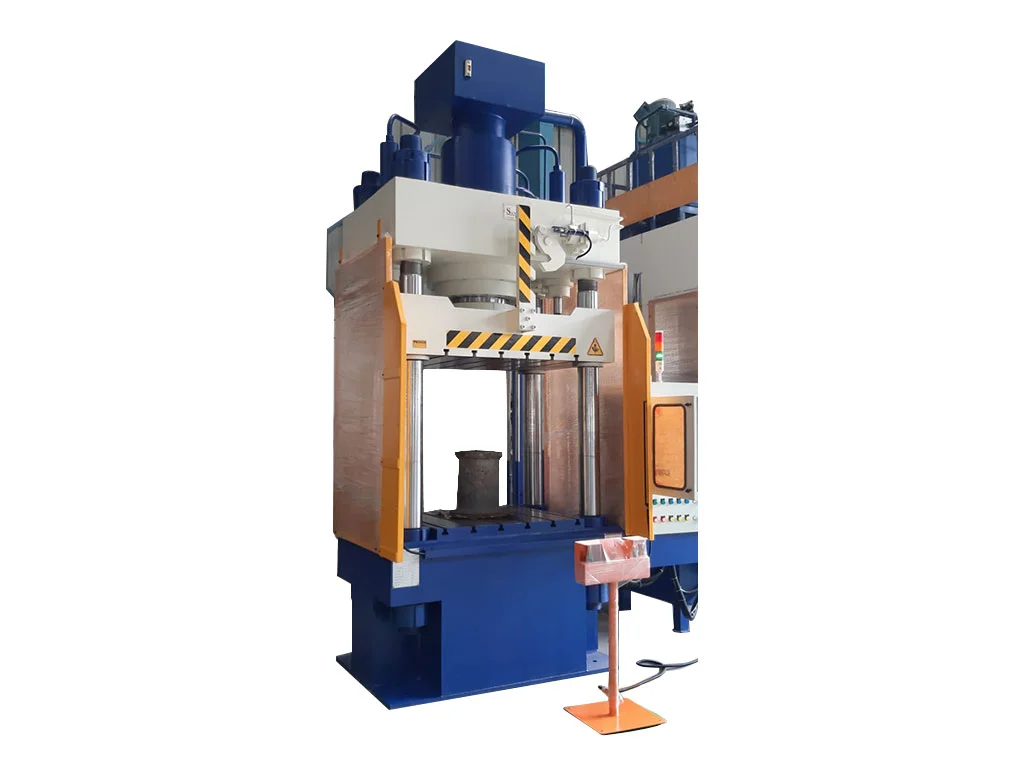

Product Overview of DMC Compression Moulding Press Machine

Industries such as automotive, electrical, aerospace, and consumer goods require advanced molding solutions. The DMC Compression Moulding Press Machine delivers reliable, efficient production of high-quality moulded parts. Its precise engineering and robust build provide consistent results, durability, and energy savings.

---

What is a DMC Compression Moulding Press Machine?

A DMC (Dough Moulding Compound) Compression Moulding Press Machine is a specialized industrial press used for moulding thermosetting plastic compounds into various complex shapes. The machine applies heat and pressure simultaneously to transform raw material into finished parts with excellent strength and surface finish. It is widely used in industries that require high dielectric strength and flame-resistant, moulded components.

---

Applications in Industry

The machine finds applications in various sectors, including:

* Automotive Industry – for manufacturing lightweight yet durable components.

* Electrical and Electronics – for switchgear, insulators, and circuit components.

* Aerospace and Defence – for precision-engineered composite parts.

* Consumer Goods – for producing high-strength everyday products.

---

Why is the DMC Compression Moulding Press Machine your best investment?

This machine excels because it delivers Consistency in quality, ensuring complete uniformity in every production run.

* Energy Efficiency – dramatically reduces power usage compared to conventional moulding systems.

* High Productivity – enables large-scale production with minimal downtime.

* Durability – built with heavy-duty materials for long-lasting performance.

---

About Santec Group Corporation – Manufacturer in Delhi

Santec Group Corporation in Delhi manufactures and supplies DMC Compression Moulding Press Machines. Santec is committed to innovative engineering and quality, earning strong recognition in both local and international markets. The company focuses on customer satisfaction with reliable, durable, and competitively priced machines. Santec serves both small and large manufacturers to maximize the value of your investment.

DMC Compression Moulding Press Machine

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Delhi

₹750,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Heavy-duty frame construction for durability.

- PLC-controlled operations for precision and automation.

- Efficient hydraulic system for smooth performance.

- High-pressure and temperature capacity for quality moulding.

- Easy-to-use operator interface with safety features.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Type | Hydraulic Compression Moulding Press |

| Capacity | 50 to 2000 Tons (customizable) |

| Platen Size | 400 x 400 mm to 2000 x 2500 mm |

| Heating System | Electrical / Steam / Oil heating |

| Temperature Range | Up to 300°C |

| Hydraulic System | Energy-efficient pumps with auto pressure control |

| Control Panel | PLC-based with HMI display |

| Operation Mode | Semi-automatic / Fully automatic |

| Safety Features | Emergency stop, safety guards, overload protection |

| Applications | Automotive, electrical, aerospace, consumer goods |

Product Benefits

-

High efficiency in large-scale production.

-

Consistent and accurate moulding results.

-

Reduced material wastage.

-

Energy-efficient operations.

-

Long operational life with low maintenance.

-

Versatile usage across multiple industries.

-

Superior quality surface finish of moulded products.

-

Enhanced operator safety with advanced controls.

-

Cost-effective manufacturing solution.

-

Environmentally friendly with reduced emissions.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

It is used for moulding thermosetting plastic compounds into durable, high-quality components.

Yes, it is designed for high-volume production with consistent results.

Yes, it is available with PLC-based automation for precise control.

Automotive, electrical, aerospace, and consumer goods industries.

Yes, Santec offers customized capacities and platen sizes.

The company is based in Delhi, India.

Santec has decades of experience in manufacturing industrial press machines.

Yes, they offer full installation, training, and maintenance services.

Yes, Santec exports machines globally.

Yes, they offer high-quality machines at cost-effective prices.

Starting price is ₹7,50,000/- onwards, depending on specifications.

Compression moulding uses heat and pressure on preheated material, while injection moulding injects molten material into moulds.

For moulding applications, hydraulic presses provide more precise control and higher pressure capacity.

With proper maintenance, it can last for 15–20 years.

Operators should use protective gear, follow safety protocols, and utilize the built-in emergency stop system.