Product Overview of Lab Dispersion Kneader

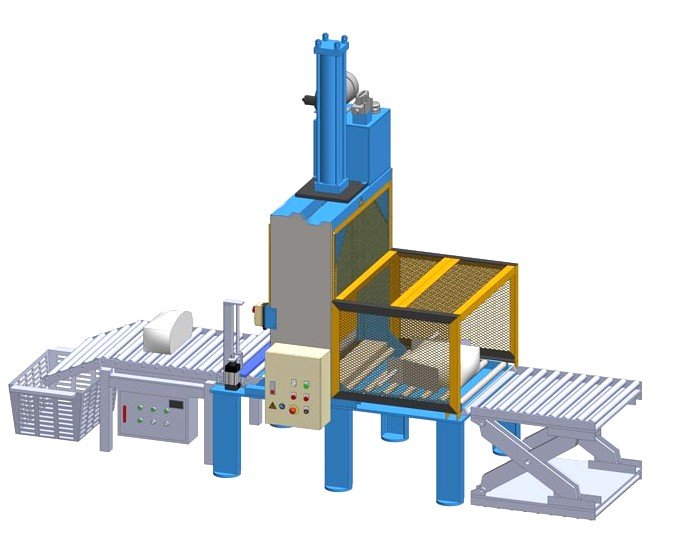

A Lab Dispersion Kneader is a specialized machine designed to handle mixing, blending, and kneading tasks for rubber, plastic, silicone, and other polymer-based materials. It is widely used in laboratories and pilot plants where testing, quality checks, and sample production are carried out before scaling up to industrial processes. This machine provides uniform mixing with high efficiency, ensuring consistent material quality and optimal performance.

Functionality and Applications

Lab Dispersion Kneaders are engineered with a tilting mechanism, mixing chamber, and robust rotors that enable even distribution of materials. They are primarily used in industries such as rubber, plastics, silicone, chemicals, pharmaceuticals, and polymers. With precise temperature control and compact design, this equipment ensures accurate results in material testing and batch production.

In laboratories, the kneader is a vital tool for R&D teams, enabling them to optimize formulations and enhance product quality. It is ideal for testing new compounds, ensuring homogeneity, and minimizing wastage during the development phase.

Advantages of Using Lab Dispersion Kneader

Lab Dispersion Kneaders save time, improve productivity, and reduce manual effort. Their closed mixing chamber prevents contamination, while the advanced controls ensure precise monitoring of temperature and pressure. This makes the machine both user-friendly and cost-efficient for laboratories.

About Santec Group – Manufacturer & Supplier

Santec Group, headquartered in Delhi, India, is a leading manufacturer and supplier of Lab Dispersion Kneaders. The company is recognized for its innovative engineering, durable equipment, and commitment to excellence in quality. With decades of expertise in rubber and plastic processing machinery, Santec caters to industries across India and abroad. Their Lab Dispersion Kneader is highly trusted for research and pilot-scale production due to its accuracy, reliability, and modern design.

Lab Dispersion Kneader

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Delhi

₹750,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Compact design suitable for laboratory and pilot plant use.

- Advanced temperature and pressure control system.

- Heavy-duty rotors for uniform and efficient mixing.

- Tilting mechanism for easy material discharge.

- Energy-efficient with minimal maintenance requirements.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Chamber Capacity | 1 to 5 liters (customizable) |

| Rotor Speed | 20 – 60 RPM |

| Motor Power | 3 – 15 HP |

| Tilting Method | Manual / Hydraulic |

| Mixing Chamber Temperature | Up to 250°C |

| Control System | PLC/Manual options |

| Discharge Type | Tilting chamber with safety lock |

| Material | Stainless steel or alloy steel construction |

| Cooling/Heating System | Water, oil, or electric heating options |

Product Benefits

-

Ensures consistent and homogeneous mixing.

-

Saves time and enhances productivity in labs.

-

Reduces material wastage during testing.

-

Easy operation with user-friendly controls.

-

Compact structure requires less space.

-

Reliable performance with durable construction.

-

Low maintenance costs and long service life.

-

Suitable for various materials like rubber, plastic, and silicone.

-

Improves research and development efficiency.

-

Provides accurate results for quality testing.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

For mixing, kneading, and testing rubber, plastic, and polymer materials in labs.

Typically ranges from 1 to 5 liters for laboratory use.

Yes, it supports mixing up to 250°C.

Yes, it works efficiently with silicone, rubber, and plastic compounds.

Through a manual or hydraulic tilting mechanism.

Santec Group is a leading manufacturer in Delhi.

Yes, they supply machines across India and abroad.

Santec has decades of expertise in manufacturing industrial machinery.

Yes, customized designs and capacities are available.

Installation, training, maintenance, and technical support.

Approx. ₹7,50,000/-

Rubber, plastic, silicone, chemical, and pharma industries.

Ranges from 3 to 15 HP depending on model.

Yes, with user-friendly controls and automation options.

With proper maintenance, it lasts over 10–15 years.