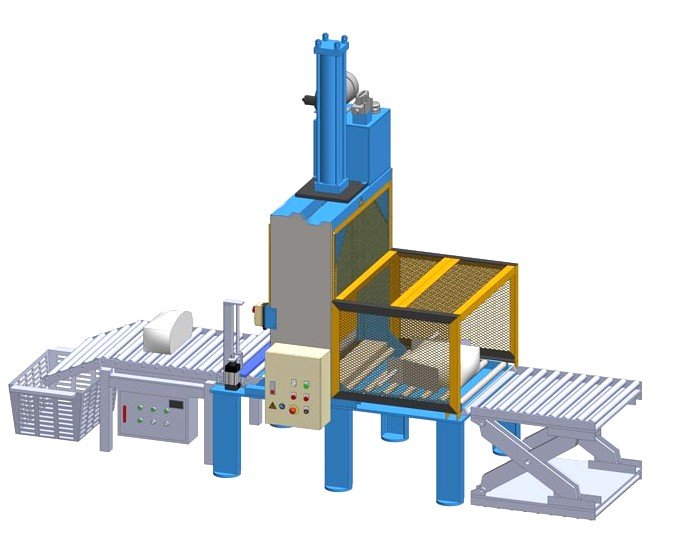

Product Overview of Lab. Type Presses

Lab. Type Presses are specialized machines designed for research, testing, and small-scale production across industries such as rubber, plastics, composites, and polymer materials. These presses are commonly used in laboratories to simulate industrial pressing conditions on a smaller scale, ensuring precise testing and analysis. Built with robust engineering and high-quality components, they offer consistent performance, durability, and user-friendly operation.

Applications of Lab. Type Presses

These presses are versatile and serve a wide range of applications, including compression molding, sample preparation, material testing, and prototype development. Industries such as automotive, aerospace, pharmaceuticals, and educational institutions rely on Lab. Type Presses for their accuracy in testing and replicating real-world conditions. They play a crucial role in quality control and research by enabling accurate material performance evaluations before large-scale production.

Design and Technology

Lab. Type Presses are manufactured with advanced hydraulic systems, ensuring uniform pressure distribution. They are equipped with digital temperature controllers and precision load measurement systems to guarantee accuracy. Safety features like emergency stop mechanisms, protective covers, and overload protection enhance operator security. Their compact design makes them suitable for laboratory spaces without compromising efficiency.

Advantages for Industries

By using Lab. Type Presses, industries benefit from precise material testing, reduced production risks, and cost savings during prototyping. These machines are indispensable in product development, as they help manufacturers understand material behavior under controlled conditions. They also reduce wastage by identifying defects early in the design phase.

About Santec Group and Its Lab. Type Presses

Santec Group, headquartered in Delhi, is a trusted manufacturer and supplier of high-performance industrial machinery. With decades of expertise in hydraulic and mechanical systems, the company has established itself as a global leader. Their Lab. Type Presses are engineered with cutting-edge technology to cater to industries requiring laboratory-level precision. Santec’s focus on quality, innovation, and customer satisfaction has made it a preferred choice in Delhi and worldwide.

Lab. Type Presses

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Delhi

₹150,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Compact, laboratory-friendly design.

- Digital temperature and pressure control.

- High precision load measurement system.

- Energy-efficient hydraulic operation.

- Advanced safety mechanisms

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Type | Hydraulic Lab. Press |

| Tonnage Capacity | 5–100 Tons (customizable) |

| Heating System | Electrical heaters with digital temperature control |

| Temperature Range | Up to 300°C |

| Platen Size | 150 mm x 150 mm to 500 mm x 500 mm |

| Pressure Control | Precision hydraulic system |

| Power Supply | 3 Phase, 220/440 V, 50 Hz |

| Construction | Heavy-duty steel frame with compact design |

Product Benefits

-

Accurate material testing results.

-

Saves cost in prototyping and R&D.

-

Reduces chances of production defects.

-

Easy to operate and maintain.

-

Space-saving design for labs.

-

Enhances quality control processes.

-

Increases efficiency in research applications.

-

Long service life with durable construction.

-

Customizable to specific industry requirements.

-

Supports innovation in product development.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

5 to 100 tons, customizable.

Yes, it supports multiple materials.

Yes, with digital controllers up to 300°C.

Yes, it comes with overload protection and safety covers.

Yes, sizes can be tailored as per requirements.

In Delhi, India.

Yes, they supply worldwide.

Rubber, plastics, automotive, aerospace, pharma, and more.

Over three decades of industry experience.

Yes, including installation and maintenance services.

Material testing, R&D, and prototyping.

Starts from ₹1,50,000, depending on capacity.

3 Phase, 220/440 V, 50 Hz.

Yes, based on capacity and platen size.

Usually 6–8 weeks, depending on specifications.