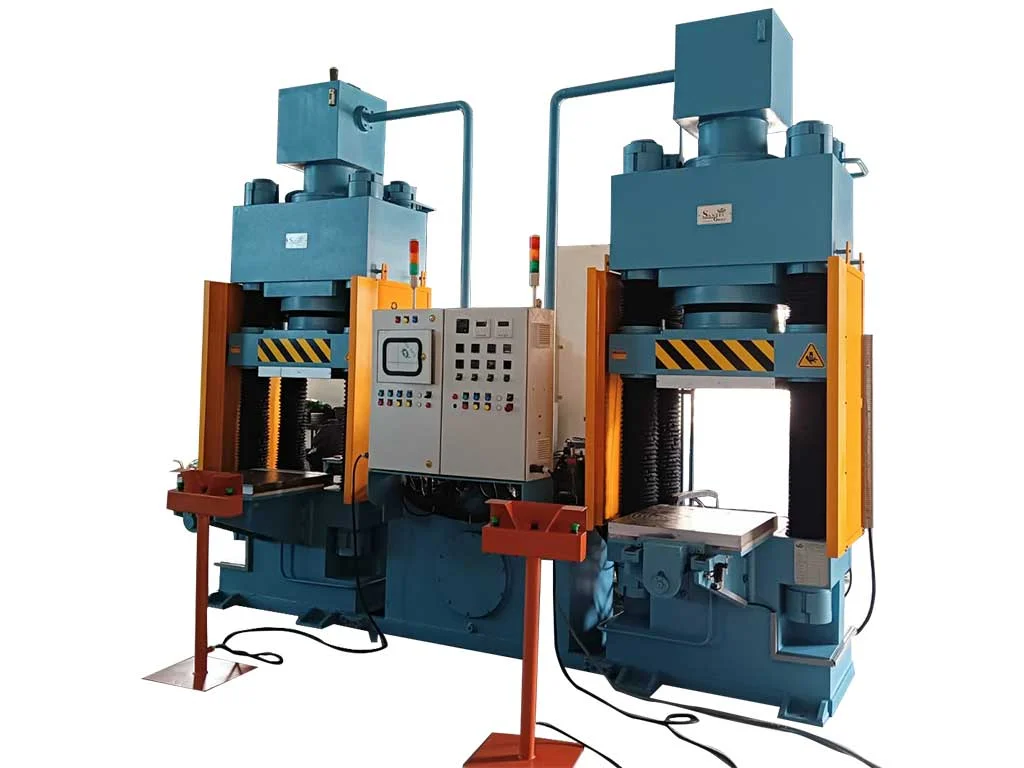

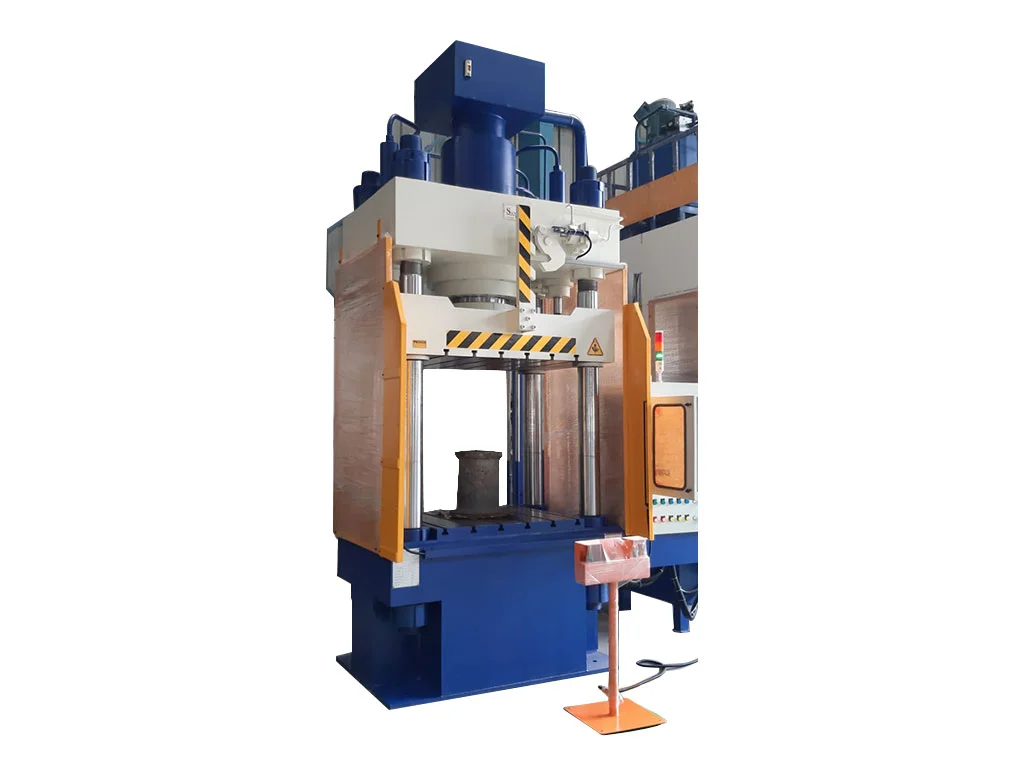

Multiplanes Compression Moulding Presses – Product Overview

Multiplane compression Moulding Presses are specialized industrial machines designed for high-performance moulding applications. These presses are widely used in industries such as automotive, aerospace, electrical, and rubber manufacturing for producing high-quality moulded components. Built with precision engineering, these machines deliver consistent pressure, ensuring flawless moulding results with superior finish and accuracy.

What is a Multiplane Compression Moulding Press?

A Multiplanes Compression Moulding Press is a heavy-duty press that applies uniform pressure across multiple planes, making it ideal for complex moulding operations. Unlike standard moulding machines, it offers advanced control, enhanced efficiency, and reduced cycle time. This makes it the ideal choice for industries seeking high productivity and reliable results.

Applications of Multiplane Compression Moulding Presses

* Rubber and plastic component manufacturing

* Automotive parts moulding

* Electrical insulation parts production

* Aerospace and defense industries

* Composite material moulding

* Heavy-duty industrial applications require precision

Advantages of Using Multiplane Compression Moulding Presses

These machines bring together strength, reliability, and innovation. They are energy-efficient, versatile, and designed to handle a wide range of materials. Industries benefit from faster turnaround times, lower operational costs, and higher-quality output.

Why Choose Santec Group Corporation in Delhi?

Santec Group Corporation is one of the leading manufacturers and suppliers of Multiplane Compression Moulding Presses in Delhi. With decades of expertise in designing and delivering advanced moulding solutions, the company ensures unmatched quality, performance, and after-sales support. Customers in Delhi and across India trust Santec Group for their cutting-edge engineering, competitive pricing, and commitment to customer satisfaction.

Multiplanes Compression Moulding Presses

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Delhi

₹450,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Robust construction with precision engineering.

- Multi-plane pressure distribution system.

- Advanced control panel with automation features.

- Energy-efficient hydraulic system.

- Long-lasting and low-maintenance design.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Capacity | 50 to 2000 Tons |

| Working Pressure | Up to 350 Bar |

| Platen Size | Customized as per requirement |

| Daylight Opening | 300mm to 1500mm |

| Stroke Length | 200mm to 1000mm |

| Heating System | Electrical / Steam / Oil heated platens |

| Control | PLC with HMI or Manual options |

| Power Supply | 3 Phase, 415V, 50Hz |

| Safety Features | Emergency stop, overload protection, and interlocking system |

Product Benefits

-

Ensures uniform pressure for consistent moulding.

-

Reduces production cycle time.

-

Enhances product quality and finish.

-

Increases overall productivity.

-

Suitable for complex moulding operations.

-

Cost-effective solution for bulk manufacturing.

-

Versatile applications across multiple industries.

-

Easy to operate and maintain.

-

Reduces material wastage.

-

Long service life ensuring maximum return on investment.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

It is an industrial machine used for moulding rubber, plastics, and composites under high pressure across multiple planes.

It is widely used in automotive, aerospace, rubber, electrical, and plastic industries.

Yes, Santec Group offers customization in capacity, platen size, and control systems.

It provides uniform pressure across multiple planes, ensuring higher accuracy and quality in moulding.

The starting price is approximately ₹4,50,000/-.

Santec Group Corporation is a leading manufacturer and supplier of moulding and hydraulic presses in Delhi.

Santec Group has decades of experience in manufacturing advanced industrial machines.

Yes, Santec Group provides full after-sales service, including maintenance and spare parts.

While headquartered in Delhi, the company supplies machines across India and internationally.

Yes, installation and operator training are included with every purchase.

With proper maintenance, it can last over 15–20 years.

Consumption depends on the capacity and usage but modern systems are designed to be energy-efficient.

Yes, it is ideal for moulding composite materials under high pressure.

Emergency stop, overload protection, and interlocks for operator safety.

It depends on the material, product size, and production volume. Santec experts guide you to select the right model.