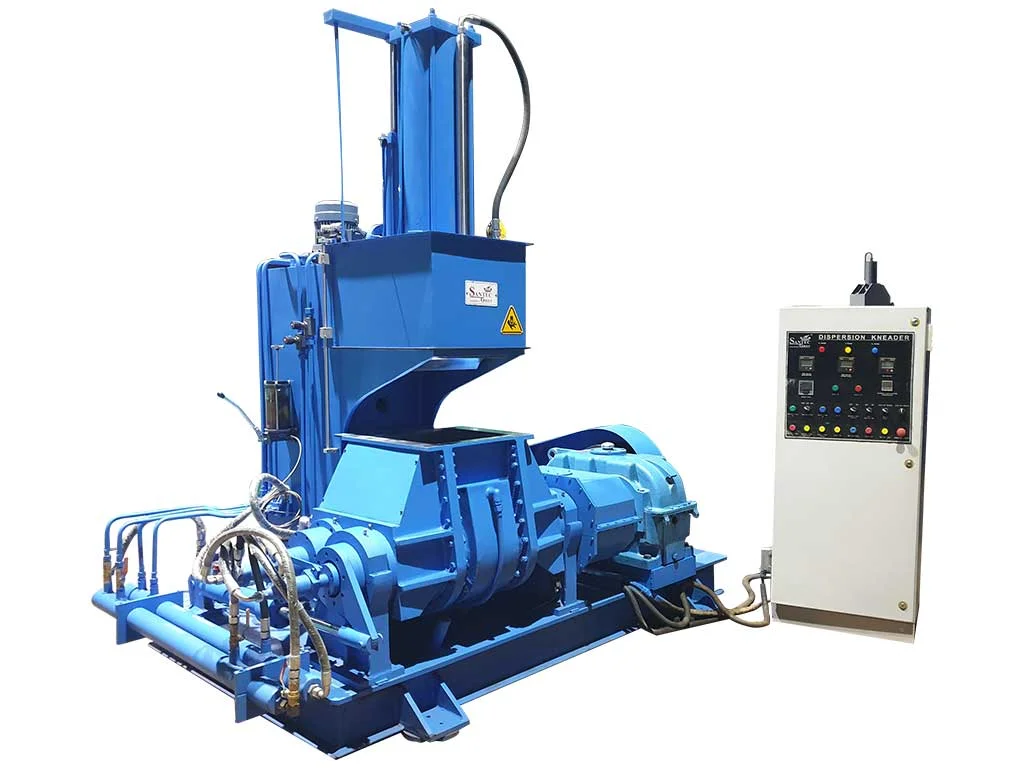

Product Overview: Plastic Palletizing Line for Masterbatches

The plastic industry demands advanced machinery to produce high-quality masterbatches that meet global standards. A Plastic Palletizing Line for Masterbatches is an essential system designed for efficient compounding, extrusion, and pelletizing of polymer-based materials. This line ensures uniform color dispersion, consistent granule size, and optimal processing performance, making it ideal for industries involved in plastics, packaging, automotive, and consumer goods.

Advanced Technology for Masterbatch Production

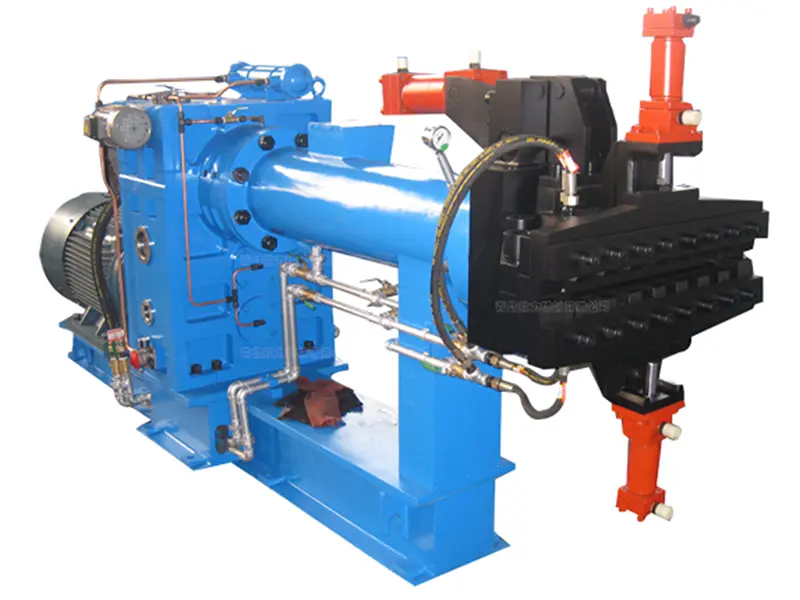

A plastic palletizing line integrates extruders, pelletizers, cooling systems, and conveying units to process polymers with additives, pigments, and fillers. The system is designed for high productivity, precision, and energy efficiency. With automated controls and advanced screw design, it ensures consistent mixing and output quality, meeting the needs of industries requiring colored and functional masterbatches.

Efficiency and Performance

The line is designed to handle various polymers, including PE, PP, PET, and PS, offering flexibility in masterbatch production. It ensures high throughput, stable operation, and minimal energy consumption. The cutting-edge pelletizing system ensures uniform pellet size, enhancing downstream processing and ultimately improving customer satisfaction.

User-Friendly Operation and Safety

Equipped with PLC-based automation and touchscreen controls, the system offers simplified operation with minimal human intervention. Its robust construction, safety interlocks, and low-maintenance design make it a reliable choice for continuous production environments. Additionally, the modular setup allows customization based on production capacity and application needs.

Santecgroup – Leading Manufacturer in Delhi

Santecgroup, based in Delhi, is a trusted name in industrial machinery and engineering solutions. As one of the leading manufacturers and suppliers of Plastic Palletizing Line for Masterbatches, Santecgroup delivers world-class equipment engineered for durability, performance, and cost-effectiveness. With years of expertise, global reach, and strong after-sales service, the company has established itself as a preferred partner for industries seeking cutting-edge plastic processing machinery.

Plastic Palletizing Line For Masterbatches

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Delhi

₹1,200,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- High-performance extrusion system with advanced screw design.

- Uniform pellet size with precision cutting and cooling system.

- PLC-controlled automation for easy operation.

- Energy-efficient motor and heating system.

- Modular design for flexible customization.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Type | Plastic Palletizing Line for Masterbatches |

| Material Processed | PE, PP, PET, PS, and other thermoplastics |

| Output Capacity | 100 – 2000 kg/hr (customizable) |

| Extruder Type | Single / Twin Screw Extruder |

| Pelletizing System | Strand / Die Face Cutting |

| Cooling System | Water Bath / Air Cooling |

| Automation | PLC with Touchscreen Interface |

| Power Requirement | 50 – 250 kW (depending on model) |

| Build | Heavy-duty robust structure |

| Applications | Masterbatch, compounding, recycling, filler addition |

Product Benefits

-

Consistent quality of masterbatches.

-

High production capacity with reduced downtime.

-

Easy-to-operate system with minimal manpower.

-

Durable and long-lasting equipment.

-

Reduced operational costs.

-

Flexibility to handle multiple polymers.

-

Uniform dispersion of pigments and additives.

-

Low maintenance requirement.

-

Reliable after-sales support.

-

Enhanced profitability with efficient performance.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

It processes polymers with pigments and additives into uniform pellets for use in plastic manufacturing.

PE, PP, PET, PS, and other thermoplastics.

Yes, it supports capacities ranging from 100 kg/hr to 2000 kg/hr.

Strand pelletizing and die-face cutting systems.

Yes, it includes PLC-based automation for easy operation.

The company is headquartered in Delhi, India.

Yes, the company offers installation, training, and after-sales service.

Plastics, packaging, automotive, construction, and consumer goods industries.

Yes, Santecgroup provides customized solutions as per client requirements.

The company has years of expertise in manufacturing industrial machinery.

The starting price is approx. ₹12,00,000, depending on specifications.

Typically 6–12 weeks, based on customization.

Usually 1 year, with extended warranty options.

Regular cleaning, lubrication, and scheduled servicing ensure longevity.

Yes, it can be adapted for recycling and compounding applications.