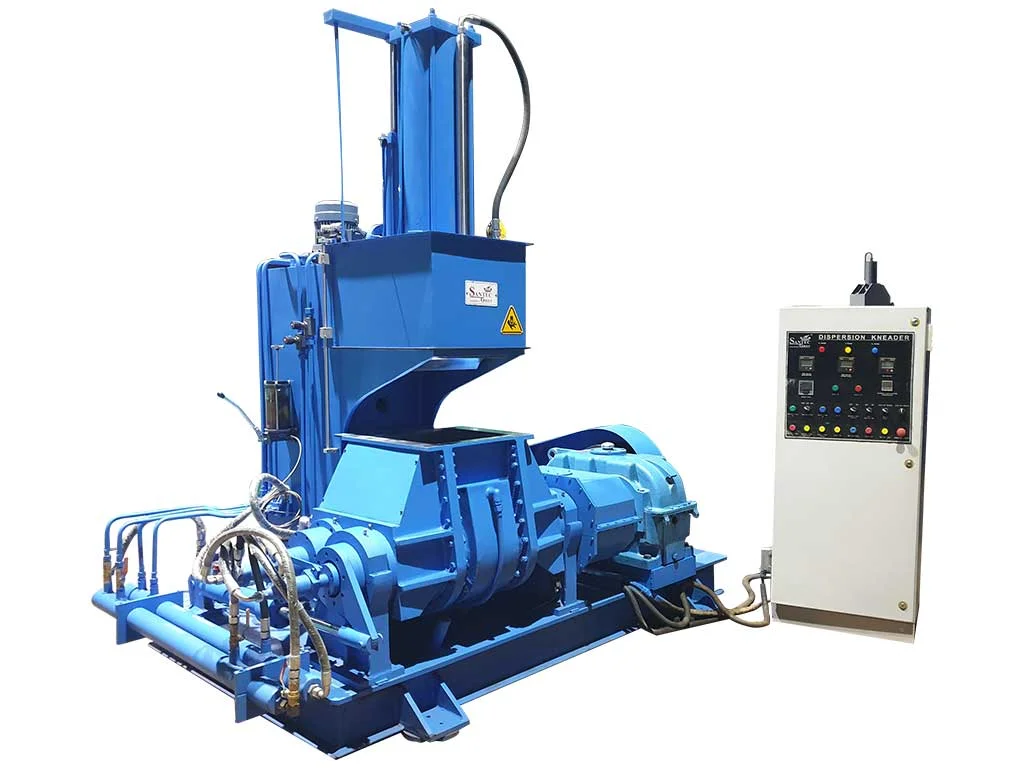

Rubber Extruder Machines – Product Overview

Introduction to Rubber Extruder Machines

Rubber Extruder Machines are vital equipment in the rubber processing industry, designed to shape, process, and form raw rubber into desired profiles with precision and efficiency. They are widely used in manufacturing rubber profiles, hoses, cables, treads, and sealing components. By combining modern technology with robust performance, these machines deliver consistent output, uniform shapes, and high productivity.

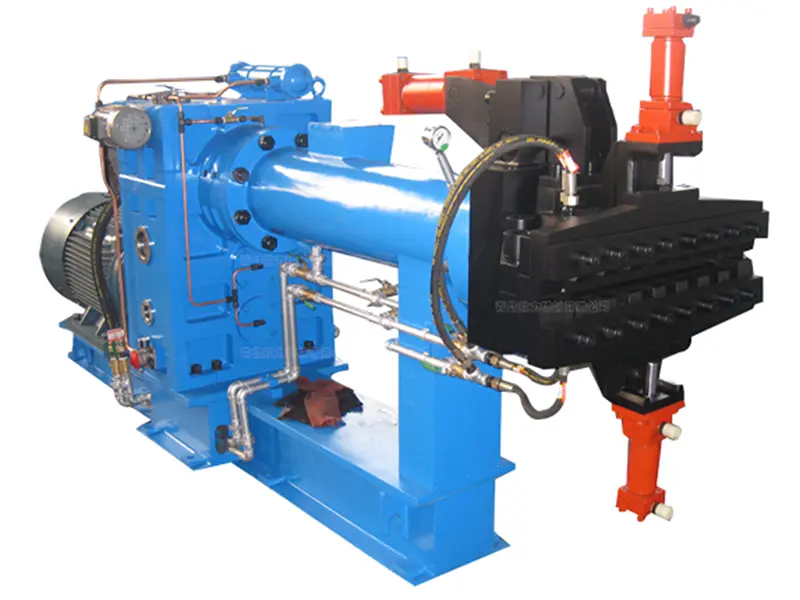

Working Principle of Rubber Extruder Machines

The extruder works by feeding raw rubber material into a heated barrel, where it is plasticized and pushed through a die with the help of a rotating screw. This process ensures that the rubber is shaped accurately according to the required design. Different dies can be used to create specific products, making the machine versatile for multiple applications.

Types of Rubber Extruders

* Hot Feed Extruders – Suitable for continuous production using preheated rubber.

* Cold Feed Extruders – Accept rubber at room temperature and are energy-efficient.

* Pin Barrel Extruders – Designed for maximum homogenization and mixing.

* Vent-Type Extruders – Used for removing volatile substances during extrusion.

Applications of Rubber Extruder Machines

* Rubber hoses and pipes manufacturing

* Cable and wire coating

* Tread extrusion for tires

* Seals and gaskets production

* Automotive and industrial rubber profiles

Why Choose Santecgroup?

Santecgroup is one of the leading manufacturers and suppliers of Rubber Extruder Machines in Delhi. With years of expertise and a strong commitment to innovation, the company delivers advanced machinery that meets international quality standards. Santecgroup focuses on durability, efficiency, and customer satisfaction, making it a trusted name in the rubber machinery industry. Their Rubber Extruder Machines in Delhi are widely appreciated for their precision engineering, user-friendly design, and cost-effectiveness, serving industries across India and abroad.

Rubber Extruder Machines

Precision Engineered Hydraulic Press Solutions — Powering Performance, Productivity & Perfection.

Available in Delhi

₹450,000.00 / Per piece

Inclusive of all taxes

Established in 1998, Santec Group has grown into a globally trusted leader in hydraulic press manufacturing and industrial automation solutions.

Leading Manufacturer And Supplier in India

- Heavy-duty design with long service life.

- Precision screw and barrel for uniform extrusion.

- Energy-efficient motor and heating system.

- Easy-to-operate control panel.

- Compatible with a variety of dies for multiple applications.

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Screw Diameter | 65 mm to 200 mm |

| L/D Ratio | 12:1 to 20:1 |

| Motor Power | 20 HP to 150 HP |

| Output Capacity | 50 kg/hr to 500 kg/hr |

| Heating System | Electrical / Steam heating |

| Cooling System | Water circulation cooling |

| Die Types | Customizable as per requirement |

| Construction | Heavy-duty steel body with precision machining |

Product Benefits

-

Ensures consistent product quality.

-

Reduces production downtime.

-

Versatile machine for multiple rubber products.

-

Saves energy with modern efficiency systems.

-

Provides smooth, uniform extrusion output.

-

Enhances productivity in rubber processing.

-

Low maintenance requirements.

-

User-friendly operation with safety features.

-

Supports large-scale industrial applications.

-

Cost-effective investment for long-term use.

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

It shapes raw rubber into continuous forms like hoses, profiles, and cables.

Natural rubber, synthetic rubber, and other elastomers.

Yes, dies can be designed as per specific production requirements.

Yes, especially hot feed extruders are widely used in tread manufacturing.

Ranges from 50 kg/hr to 500 kg/hr, depending on the model.

The company is based in Delhi, India.

Yes, they provide installation, training, and maintenance support.

Yes, Santecgroup supplies machines globally.

Yes, machines can be customized based on client requirements.

The company has decades of experience in manufacturing rubber machinery.

Typically 10–15 years with proper maintenance.

Starting price is around ₹4,50,000/- and varies by model and capacity.

Automotive, cable, construction, footwear, and industrial sealing industries.

Basic training is recommended for safe and efficient operation.

Regular lubrication, screw and barrel inspection, and die cleaning are essential.